Testimonials

At BW Packaging, we take pride in a job well done, a bag well made, and product well handled. But we also know that your business is more than just "product"; it's the years of R&D that went into developing your offerings—whether that's frozen pasta that eats like it's fresh made, or nutrition bars, or pet food, or anything else—and it's the people in your building, working to a shared vision.

Don't just take our word for it, though. Hear a few of our customers discuss how BW Packaging helped them find their packaging solutions. And when you're ready, let's talk about your packaging solution.

Vertical Bagging Success Stories

Pearson Foods | Fresh Produce

Pearson Foods, an innovative fresh foods company located in Grand Rapids, MI, recently added the Hayssen ISB vertical form-fill-seal bagger to its fresh produce packaging lines, which also feature legacy Hayssen Ultima baggers.

After months of watching and measuring, Pearson determined that it can run the ISB bagger 18-22% faster than the other older machines on site.

Pearson Foods' new 19-year-old ISB operator—who had no previous packaging equipment experience—learned to effectively operate the machinery within 2 days of training, which was made even easier as the ISB can be switched to Spanish with the simple push of a button.

"The machine is intuitive," Nelson said. This combination of intuitive design and ease of operation makes the challenges presented by labor shortage and high employee turnover a non-issue.

Visit our blog to read more about Pearson Foods' story.

Equipment: Hayssen Vertical Form Fill Seal

Surgital SPA | IQF Pasta & Meals

Surgital, an artisanal pasta and foods company in Italy, is renowned for their outstanding quality and flavors. But how do you package a fragile product like fresh-made pasta so that it can be safely delivered to stores and hungry fans around the world? With the same care and attention that went into make it.

Here, Surgital's Edoardo Bacchini discusses their history, the challenges they faced, and why it was so important to find the right packaging partner for his carefully-made foods.

Visit our blog to read more about Surgital's story.

Equipment: Hayssen Vertical Form Fill Seal

Crest Foods | VFFS Packaging Upgrades

"The field technicians—I have to admit—are just extraordinary. Just some really good, down home people that want to talk and interact directly." -Rick Rice, Controls Engineer/Project Manager, Crest Foods.

Rick Rice, Controls Engineer/Project Manager at Crest Foods, sits down to speak with BW Packaging's Phil Williams to discuss their experience with their long-serving Hayssen Ultima vertical baggers and their satisfaction with the upgrades offerings, service, and support offered to them to keep their machines running long into the future.

Solutions: Hayssen Ultima VFFS Machines, Equipment Upgrades

Flow Wrapping Success Stories

The Killer Brownie Co. | Bakery & Confectionery

In early 2020, Killer Brownie began looking for a packaging solution by sending samples to several packaging machinery suppliers. BW Packaging responded with questions of our own. After several more samples, tests, and trial runs, BWP found a suitable packaging solution for Killer Brownie's range of products: a Rose Forgrove Merlin Blu horizontal flow wrapper.

What happened next was a partnership that delivered more than just machinery!

Visit our blog to read more on The Killer Brownie Co.'s story.

Equipment: Hayssen Flow Wrappers

The Nutrition Group | Bakery & Bars

When the Nutrition Group PLC, a contract manufacturer of protein bars, set their sights on being the UK's biggest producer of protein bars, they knew they would need to ramp up their production.

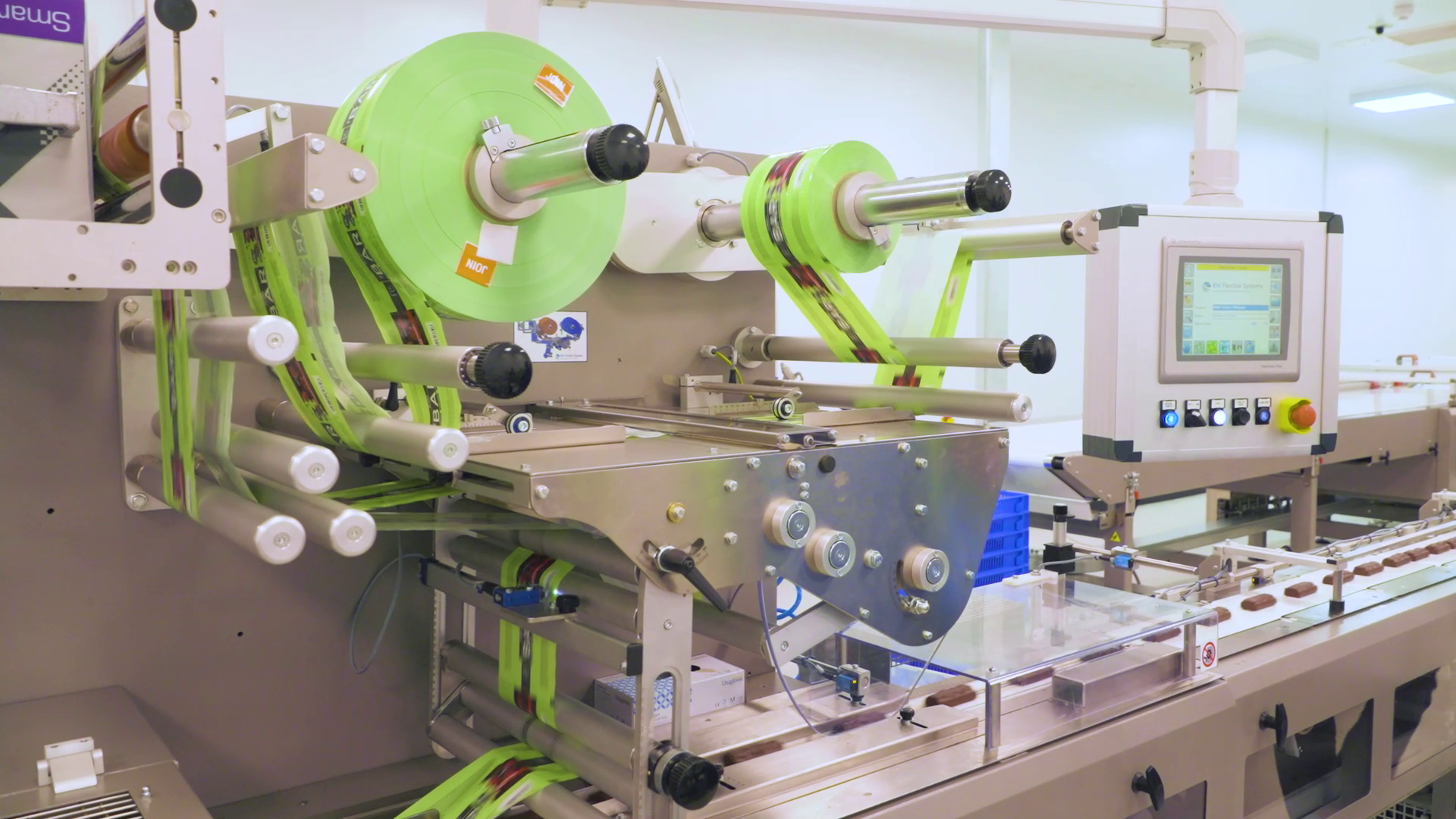

In 2018, the Nutrition Group began looking for a partner to help them increase their capacity and meet their customer's demands with a new flow wrapping solution.

"We were just very impressed with the team and felt they were the right people to work with." - Richard Greathead, CEO, Nutrition Group PLC

Equipment: Hayssen Flow Wrappers, Horizontal Feed Systems

Bag Filling & Palletizing Success Stories

East Point Potatoes | Produce Palletizing

East Point Potato, a successful family-owned potato packaging operation, has experienced steady growth since opening its doors in 2009, and today they package potatoes for upwards of thirty farmers on Prince Edward Island. Their packaging operations began as manual labor, but the increasing workload meant they needed to explore packaging solutions to help them meet demand. They turned to Symach palletizers.

"We've run this year from 7am until 11pm, five days a week." said Boyd Rose, co-owner of East Point Potato, speaking of the increased production the Symach palletizers have provided. "I would have a tough time finding crew that would pack bags on a pallet for those types of hours."

Equipment: Symach Palletizers

The Honest Kitchen | Animal Nutrition

A loyal following and a surge in production demand is The Honest Kitchen story. Their high standards in quality for pet food have set them up for rapid growth and long-term success.

Almost immediately after opening the factory in Los Angeles, THK realized quickly that the company had outgrown its facility and needed to expand to meet its customers' demands, creating a project scope with stringent deadlines, high expectations, and the need for a vendor who could supply an end-to-end solution.

How does a company go about upgrading its production while retaining its strict quality and safety standards? By working alongside an OEM with vast experience in the pet food industry. BW Packaging's total system solution for pet food and our mutual high standards for safety and quality made this partnership a perfect fit.

Visit our blog to read more about The Honest Kitchen's story.

Equipment: Thiele Bag Filling, MasterWeigh Scales

Next Level Pet Food | Animal Nutrition

Known for their uncompromising quality, Next Level Pet Food needed to scale up their operations. With an ambitious timeline, they turned to Symach and Thiele to handle their bag packaging and palletizing needs. In this video, you'll learn about why they reached out to BW Packaging, how we worked together to meet their needs and expand their packaging and palletizing capabilities, and how their new packaging line is positioning them for continued success and growth.

Equipment: Thiele UltraStar, Symach Mach Series Palletizer

Let's Talk

Contact us to discuss how our solutions can be customized to meet your requirements.

.png?sfvrsn=47a485f_1)