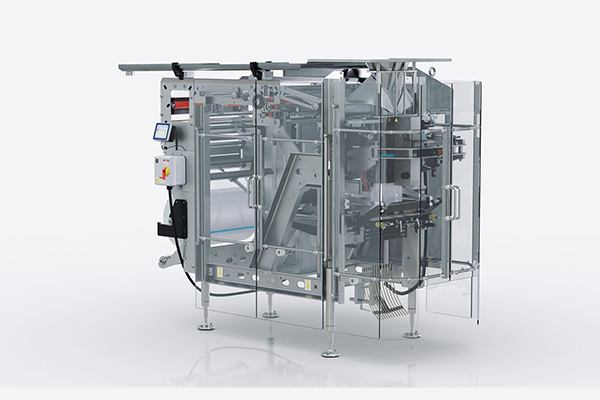

Hayssen Vertical Form Fill Seal

The BW Packaging Hayssen brand offers vertical form fill seal (VFFS) machines that deliver innovative designs and rapid, efficient throughput to meet your production demands backed by Hayssen's 100+ years of experience manufacturing and supporting packaging equipment.

“Our first stop when it comes to looking for additional bagger and scale equipment, is to go to BW.”Bruce Densten, COO Little Bear Produce

Watch the full testimonial

About Hayssen Vertical Form Fill Seal

Learn more about our vertical form fill seal machines and how this packaging machinery can fit seamlessly into your current production line. A vertical form fill seal machine can also become integral to any new system.

At BW Packaging, we take pride in offering a full line of continuous or intermittent motion machines that provide quick changeover, easy equipment integrations, and many intelligent and intuitive features that will benefit your packaging operations.

About Hayssen

For over 100 years, Hayssen has stood for reliable, innovative, and performant flexible packaging equipment and solutions. Headquartered in Duncan, South Carolina, and with facilities across the globe, Hayssen manufactures Vertical Form Fill Seal (VFFS) and Flow Wrapping machines used around the world.

Hayssen's packaging solutions have been deployed to wrap and bag products in food and food service, industrial and automotive, medical and pharmaceutical, and pet and animal food and care, and many other industries. Whether a single machine or an entire packaging line, Hayssen can deliver the flexible packaging solution to meet your needs and solve your challenges.

Our History

The Hayssen brand began in 1910, when its founder, Herman Hayssen, invented and patented the first automatic bread wrapping machine in Sheboygan, Wisconsin. The first machines were manufactured in Mr. Hayssen's garage with the help of just one mechanic.

Hayssen was a privately-held and family-owned company from 1910 until 1966, when it became a wholly-owned subsidiary of the Bemis Company, a principal manufacturer of packaging materials and specialty coated and graphics products headquartered in Minneapolis, Minnesota. In May, 1997 Hayssen was acquired by Barry-Wehmiller and is now a BW Packaging brand.

What is a Vertical Form Fill Seal Machine?

Vertical Form Fill Seal (VFFS) machines are used in almost every industry. These bagging machines are used to package goods in a production line.

The BW Flexible Systems VFFS packaging machines feature a variety of continuous and intermittent motion bag filling systems. Our vertical bagging machines are capable of filling low, medium, and high-speed packaging applications for a variety of products and industries.

Vertical bagging machines can provide packaging across multiple industries including fresh food, frozen food products, household goods, and more.

How Does a Vertical Form Fill Seal Machine Work?

The vertical form fill seal machines offered by BW Flexible Systems are a 3-in-1 solution for your flexible packaging needs.

The process begins by forming bags from a roll of film. This occurs around a forming tube, which shapes the film into the correct bag size. After forming the bag, the machine fills the bag with product and seals the product for shipment.

Depending on how product packaging requirements, a VFFS machine can also add a date/batch code, a tear notch for easier opening or a hole punch to allow the bag to hang on a display.

One machine in your production line from the BW Flexible Systems can form the bag, fill it with your product, and seal it at speeds of 100 bags per minute.

Benefits of BWFS Vertical Form Fill Seal Machines

BW Flexible Systems offers a wide variety of packaging solutions including VFFS machinery. When you choose BW Flexible Systems as your vertical form fill seal machine manufacturer, you receive more than a superior product. We believe that our customers are our partners and are committed to ensuring that your vertical bagging machine is supported by our local technicians.

Do Rose Forgrove, Sandiacre, Simionato, and Schib still exist under their original names?

While their Rose Forgrove, Sandiacre, Schib, and Simionato names may still appear in service references, they are now part of the unified BW Packaging group, specifically united under the Hayssen brand. Their legacy technologies and innovations continue to drive product development and customer success globally.

Hayssen Flow Wrappers | Hayssen VFFS Baggers

-1_adobe-stock.jpeg?sfvrsn=470e485f_2)