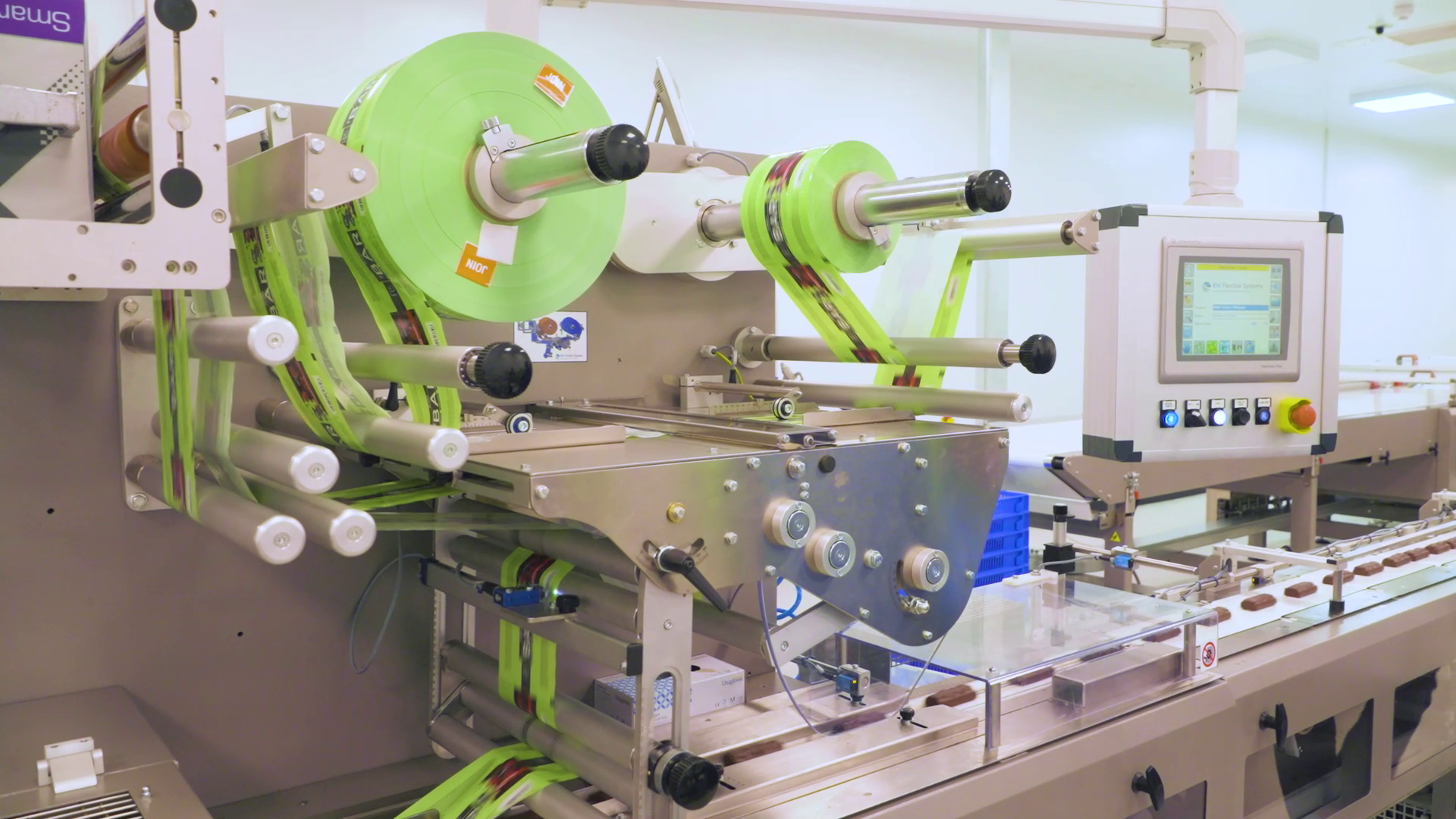

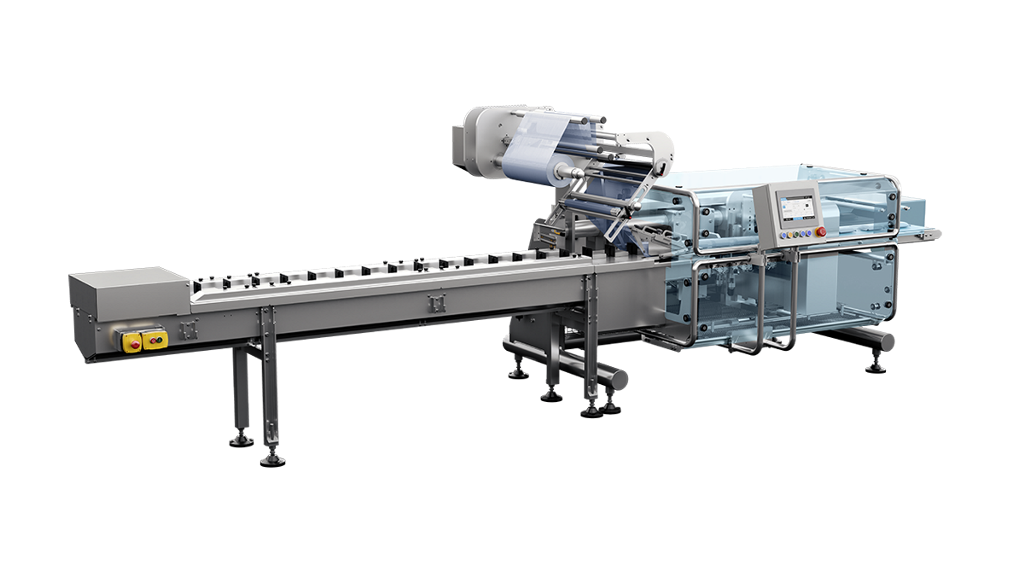

Hayssen RT2000 Flow Wrapper

About this machine

The Hayssen RT2000 is a high–speed capable horizontal flow wrapper built to seal at high speeds and designed to operate in any environment.

Bring Hayssen's advanced engineering, updated hygienic design, and product and package versatility to your production line with BW Packaging.

Hayssen RT2000 Features

The Hayssen RT2000 stands out in its class, and can be used to fill, form, and seal an array of film structures for a wide range of products. Featuring a unique long dwell sealing system and rugged , hygienic design it is one of the most versatile HFFS machines on the market.

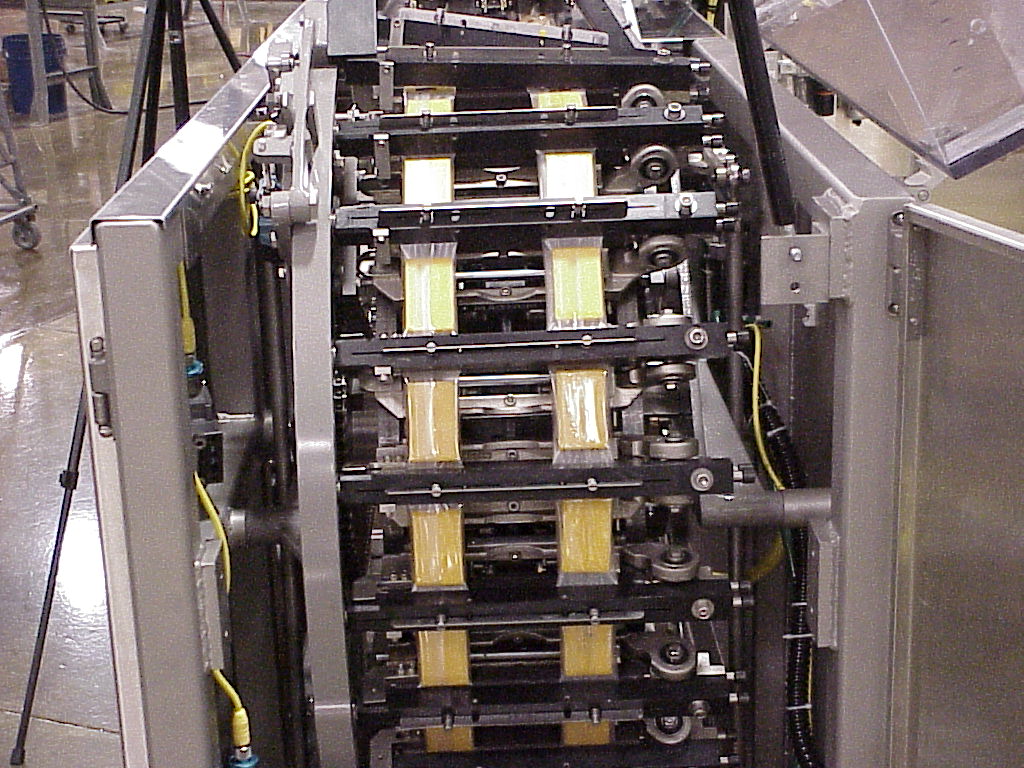

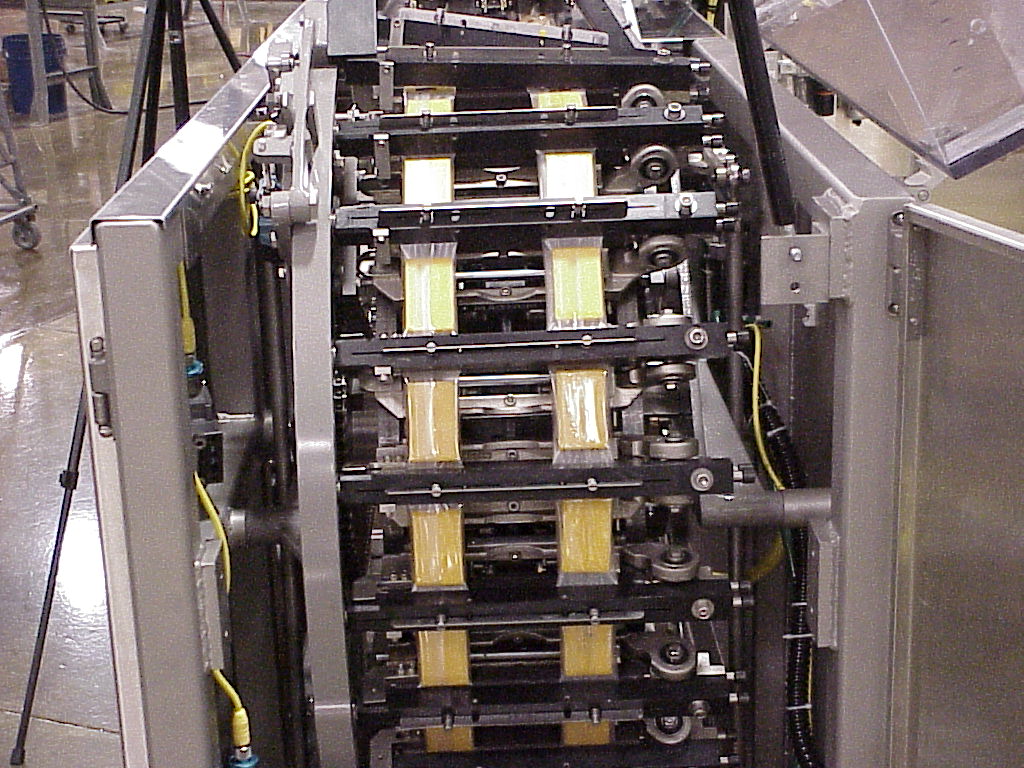

Unique Long Dwell Sealing System

The RT2000 HFFS employs a long dwell sealing system, making it an excellent choice to handle high–speed packaging lines that require hermetic seals. The incorporated MAGNUM® dies feature closed loop heat control with high & low heat temperature alarms for individual dies and deliver improved end seals.

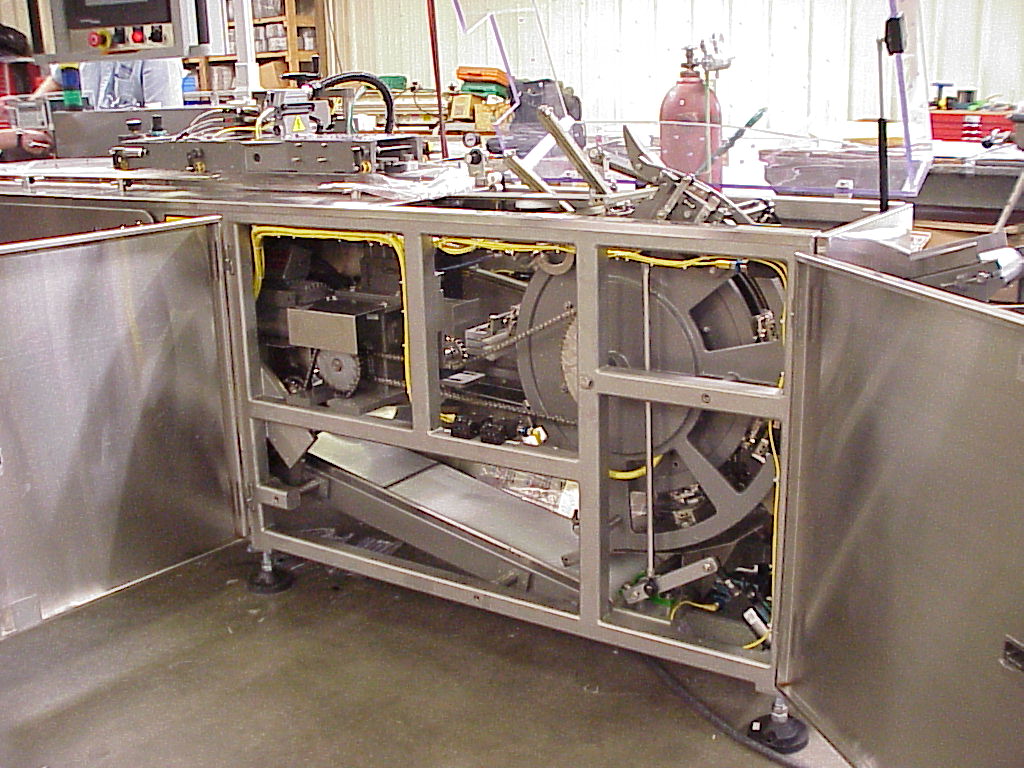

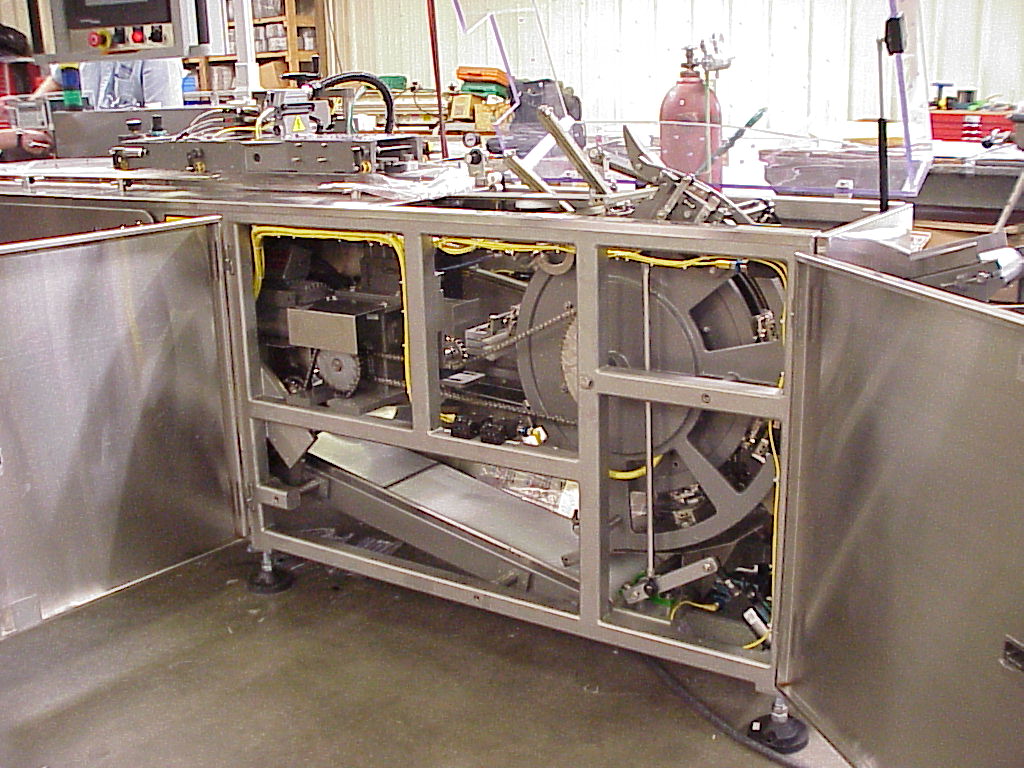

Hayssen's Strong Hygienic Design

The RT2000 delivers Hayssen's hygienic performance to your line, developed through years of research, development, and customer feedback. Its tubular front and rear frame allow for easy access to aid in cleaning and maintenance. The machine is built to withstand harsh operating environments and stringent sanitation procedures.

Optionally, the RT2000 is offered with a full stainless–steel construction. This helps the machine function in challenging environments requiring the strongest hygienic performance.

Versatile Design

In addition to its advanced hermetic sealing system, the Hayssen RT2000 excels at modified atmosphere packaging (MAP) and can be outfitted for gas flushing for one or two gases.

The Hayssen RT2000 is available in both single and dual lane configurations. It can be equipped with BW Flexible Systems' advanced product placement monitoring and alignment systems, such as product jam detection and misplaced product detection.

Product Details

Production Rate- Up to 200 pkg/min or linear film speed of 2000 inches per minute

- High speed option allows for 250 pkg/min

- Dual lane option allows for 500 pkg/min

- Width

- Minimum: 1.75" (45mm)

- Maximum: 13" (330mm)

- Length

- Minimum: 4.25" (108mm)

- Maximum: 14" (355mm)

- Height

- Minimum: 0.5" (13mm)

- Maximum: 3" (76mm)

- 230 vac, single phase, 50/60 hz, 30 amp service

- Air Supply: 3 scfm @ 65 psi

Technical Data

- Unique die wheel design concept offers an extended sealing dwell time to produce the best seals in the world at increased speeds

- Perfect for modified atmosphere (MAP) requirements

- Change package size without any parts change

- Allen-Bradley Controls with color touch screen

- Tubular frame offers accessibility and built to withstand severe operating environments and stringent sanitation procedures

- Dual lane model available for smaller packages and higher speeds

- Optional C-fold package style with multiple reclose options

- Cantilevered pneumatic film spindle

- Separate motor drive on discharge conveyor tabletop chain

.jpg?sfvrsn=b902485f_4)