Hayssen Integra

.jpg?sfvrsn=b902485f_4)

.jpg?sfvrsn=c102485f_3)

.jpg?sfvrsn=b902485f_4)

.jpg?sfvrsn=c102485f_3)

About this machine

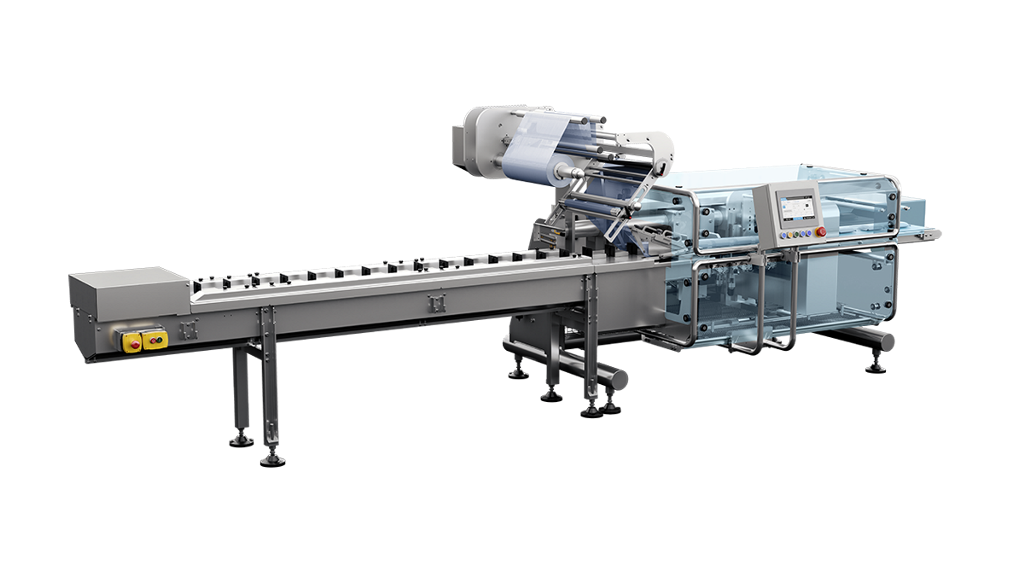

Your production line has unique needs, which all your machines must meet to ensure the production schedule does not fall behind and quality does not decline. BW Packaging designs and manufactures machines that are customizable and suitable for a variety of environments and applications to meet the specific requirements of our customers.

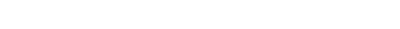

The Integra flow wrapper is suitable for both food and non-food products that require a hermetic seal using barrier, laminated, and all other heat-sealable types of films. This machine is available in both top reel (with the film feed from the top of the machine) and bottom reel (with the film feed from the bottom of the machine) configurations.

This flow wrapper offers both modified atmosphere packaging (MAP) and standard environments. With a programmable logic controller (PLC) system, the Integra flow wrapper operates with five independent motors and long-dwell cross sealing jaws.

Learn more about the Integra flow wrapper below and how it can integrate into your production line.

Product Details

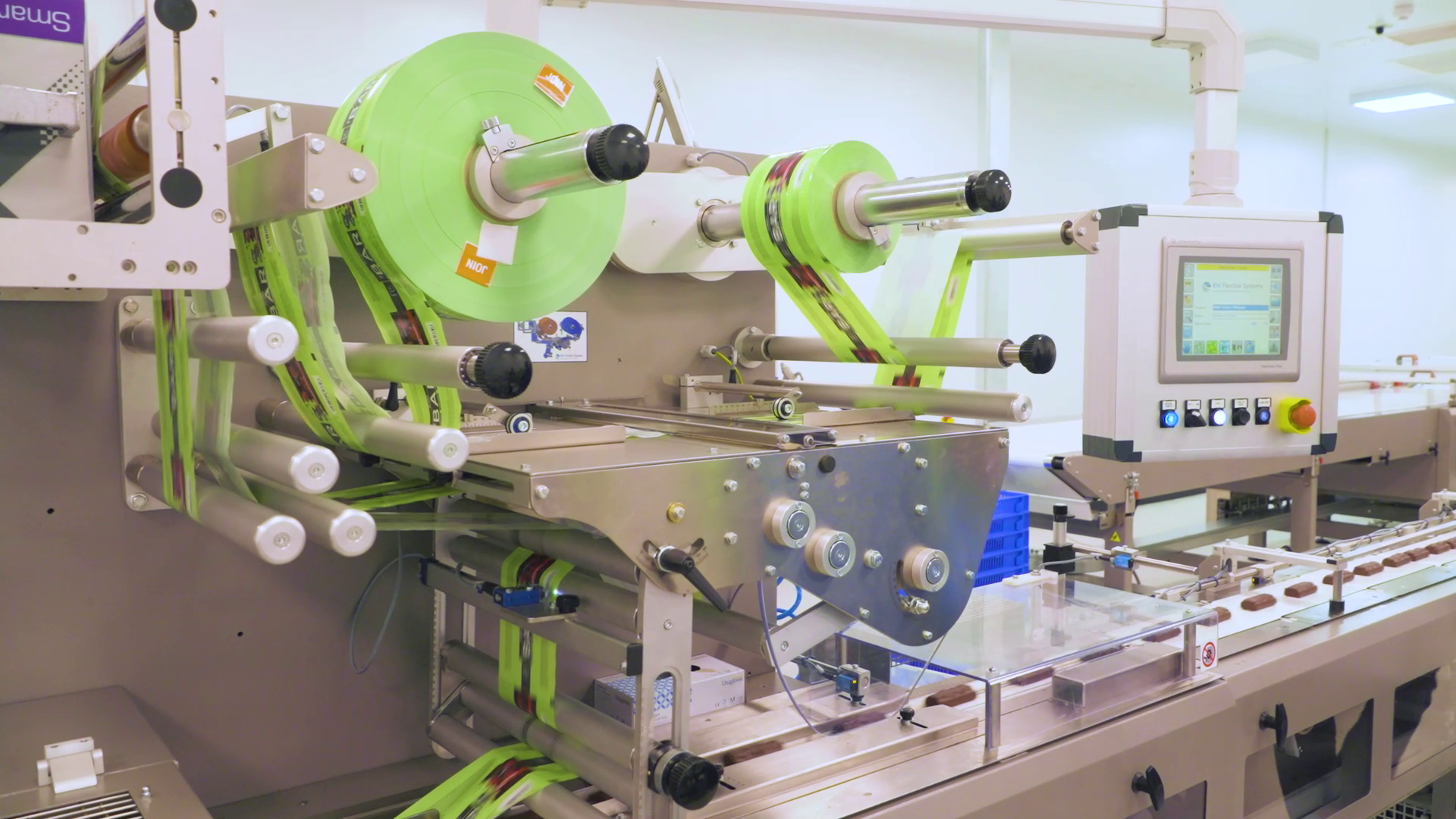

Dependable and Flexible Machine Design- Solid mechanical construction with special attention to aspects of hygiene, ease of cleaning and maintenance

- Right and left hand machines available (right hand: product flows from left to right)

- Machine finish in Stainless Steel or Painted

- 350mm max reel diameter / 76mm diameter core

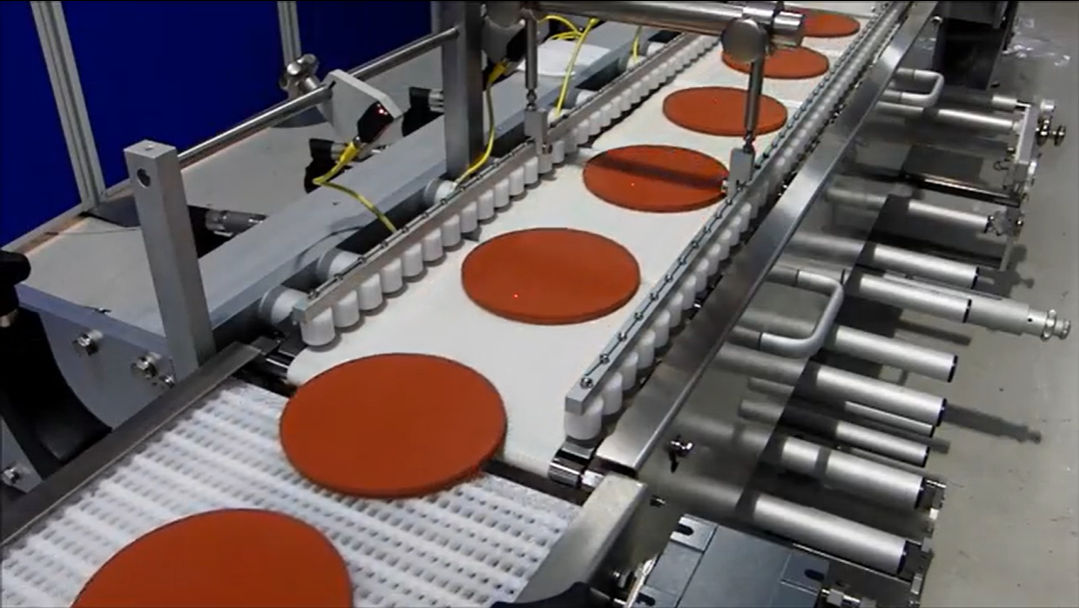

- Film fed from the top or bottom of the machine

- All parts in contact with products are stainless steel and food grade plastic

- Solid mechanical construction with special attention to aspects of Hygiene (GMP), ease of Cleaning & Maintenance and Operator Ergonomics

- Control system with industry standard Allen Bradley PLC

- Operator Interface with TFT color touch screen 10”

- Multi-axis drive technology with 5 independent axis for product infeed, longitudinal

sealing rollers, film feed, long-dwell sealing head and discharge belt - No-product / no-bag system

- Misplaced Product Detect

- Individual temperature control circuits for the 2 sets of heated longitudinal sealing

rollers - Independent temperature control on the sealing jaws integrated into control panel

- Automated product size change with all program parameters saved in product data

base, holding parameters for up to 99 different products - 6 x User defined electronic cam outputs for peripheral devices available

- Service mode for diagnostics, trouble shooting and basic machine configuration,

different level (User configurable) of password-protection - Additional user-defined password level for limiting / excluding

Technical Data

Production Rate- Up to 150ppm single jaw (film & product pending)

- Length: 50-350mm

- Width: 20-220mm

- Height: up to 150mm

- Power Supply: Europe: 380/420V 50Hz, Three Phase + Neutral

- USA: 440/480V 60 Hz, Two Phase + Neutral

- Air Supply: 6 bar