Symach Palletizers

Symach designs and manufactures palletizers and palletizing systems that increase production and are cost effective. We provide flexible, efficient, customer-specific solutions that guarantee reliable business operations, harm-free logistics processes and reduced costs. The design, improvement, calculation and detailing of customized solutions is carried out by highly motivated specialists. At Symach, we give our customers a head start and create value for people and companies, building the optimum solution for you with the utmost care and motivation.

“We probably went up about 30% in the first year. We've run from 7 AM to 11 PM, five days a week – we haven't missed a day.”Boyd Rose, Co-Owner | East Point Potatoes

Watch the full testimonial

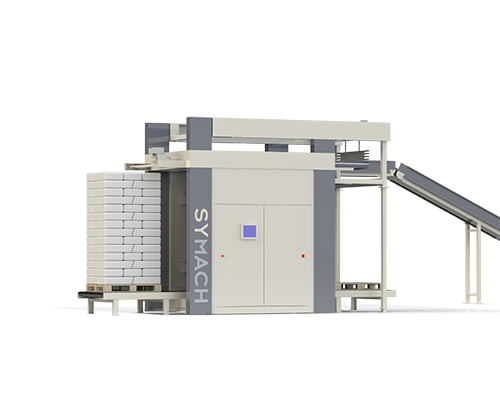

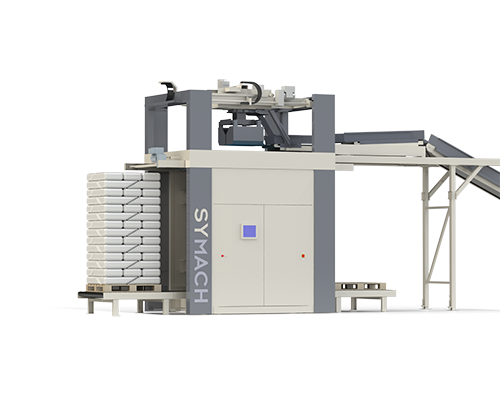

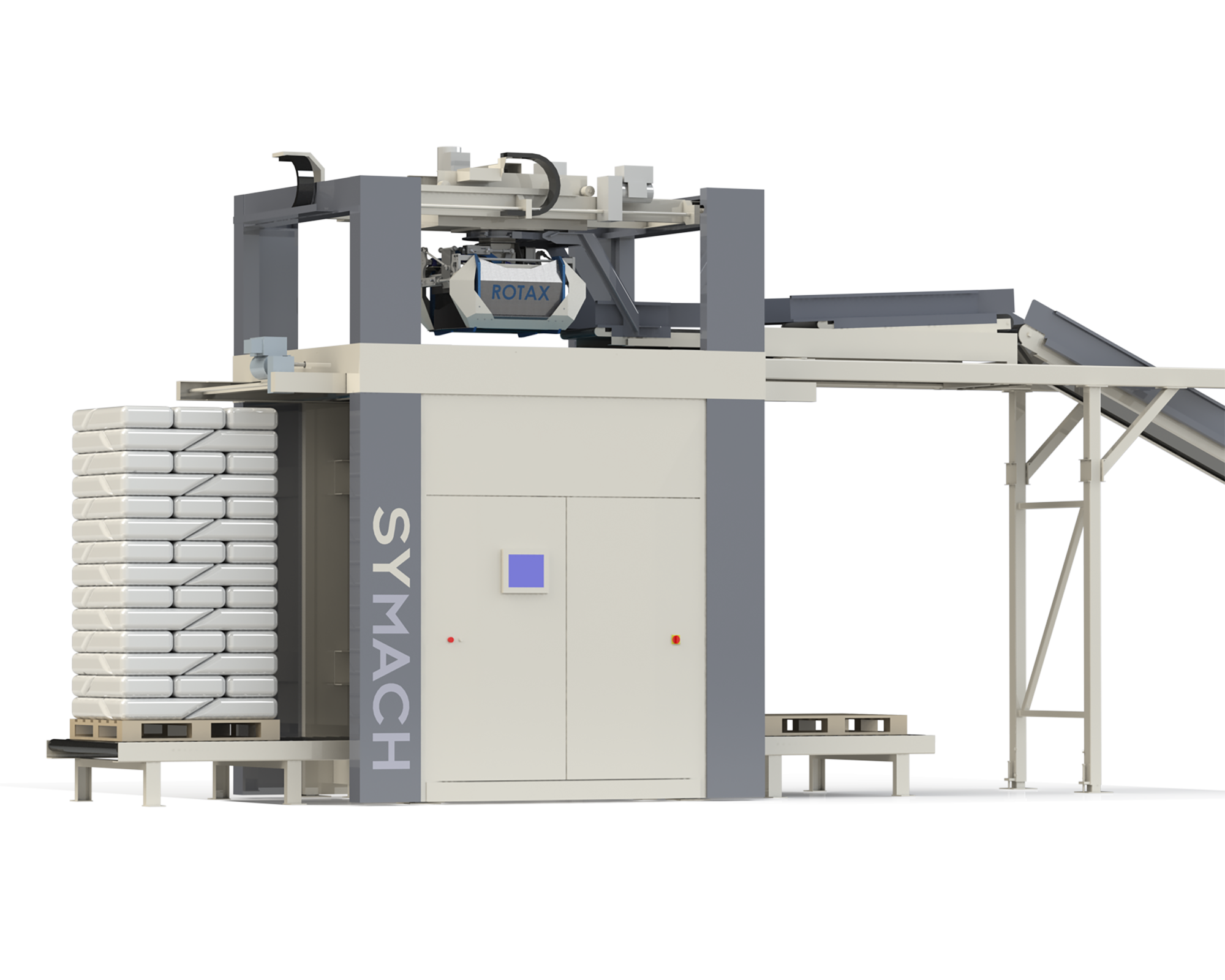

Our Featured Machines

Smart stacking: from bag to box with a single machine

Palletizing may be the last station in the line, but the stacking result is often the first thing your customer sees. With the right technology, you can ensure that every pallet looks neat, stands firmly, and can be transported without any worries. Whether you pack boxes, bags, or both, with the right SYMACH Palletizer, you always have a solution that fits.

About Symach Palletizers

Symach's automatic palletizing equipment is designed to help achieve higher speed production rates and high-quality, perfectly stacked pallet loads.

Our machines can palletize virtually any bag in a variety of sizes, shapes, or materials in stable, square pallet loads. Symach bag palletizers feature a patented layer squaring and compression system to maximize full-pallet load stability and appearance.

Bag palletizing equipment automates the pallet building process, but not all product lines are built the same. Many different palletizing accessories and technologies can be employed to help you make the perfect pallet, enabling us to customize to your needs.

At Symach, we partner with you to find the right bag palletizing equipment for your production needs.

Stronger together: Onion Tech Alliance with Symach, Eqraft and Modesta

Symach works closely with Eqraft and Modesta within OTA to deliver complete turnkey solutions for the onion and potato industry. From sorting and packaging to dust extraction and palletizing, customers benefit from a single integrated approach, with seamless coordination between the systems. Instead of focusing on supplying individual products, the OTA partners focus on the total solution. This mentality is a major added value for every agricultural factory: they benefit from the fact that all parties involved communicate with each other and are coordinated.

What is the Onion Tech Alliance (OTA)?

The Onion Tech Alliance, sometimes abbreviated as OTA, is a formal group of technology companies servicing the onion industry who have formed a working partnership to offer an integrated project approach to customers.

These companies—Symach, Eqraft, and Modesta—combine their expertise from engineering and project management to grading, wind sifting, dust extraction, weighing, packaging, palletizing and wrapping to benefit their customers and the onion industry.

Contact us to learn more or visit www.OnionTechAlliance.com